Trending Products Graphite Electrode Arc Furnace - RP Graphite Electrode for Ladle Furnace – MORKIN

Trending Products Graphite Electrode Arc Furnace - RP Graphite Electrode for Ladle Furnace – MORKIN Detail:

The Classification of Graphite Electrodes

Electric arc steel making furnace could be divided into regular power electric furnace (about 300KVA per ton), high-power electric furnace (about 400kVA per ton) and ultra-high-power electric furnace (500 ~ 1200KV/A per ton) according to transformer capacity per ton of furnace capacity.

According to the classification of electric power level of electric furnace steel making, and according to the differences of raw materials used in electrode production and physical and chemical indexes of finished electrode, graphite electrode is divided into three varieties: regular power graphite electrode (RP), high power graphite electrode (HP) and ultra-high power graphite electrode (UHP).

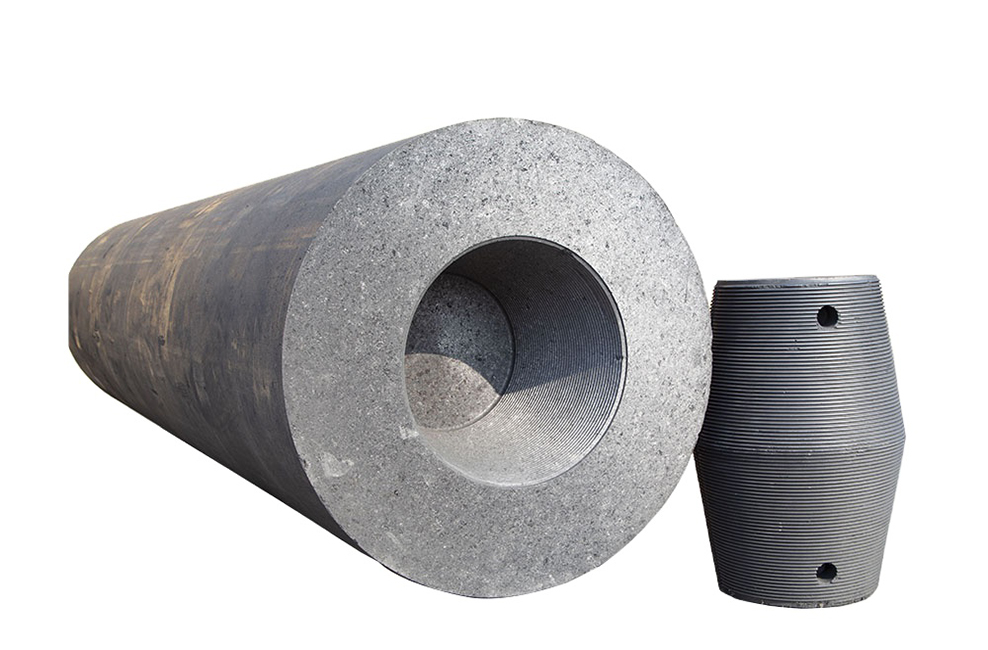

The Introduction of RP Graphite Electrode

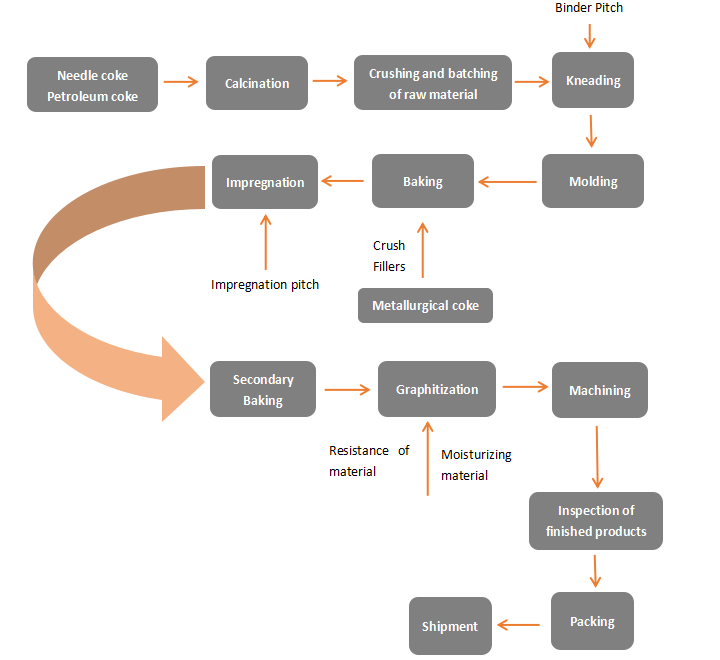

RP graphite electrode is mainly made of petroleum coke as raw materials and coal asphalt as binder through calcination, batching, kneading, molding, baking, graphitization and machining.

Graphite Electrode is a conductor that releases electric energy in the electric arc furnace to heat and melt the steel scrap.

Features

RP graphite electrode is produced with petroleum coke, with low graphitization temperature. it has the following features:

1.High resistivity

2.Large linear expansion coefficient

3.Poor thermal shock resistance

4.The allowable current density is low

The Application of RP Graphite Electrode

(1) For steel making in Electric Arc Furnace (EAF) and Ladle Furnace (LF)

RP Graphite electrode is mainly used in LF/EAF for steel making. When graphite electrode is working in LF, the current will be introduced by graphite electrode into the furnace, and there will be heat source which is generated by electric arc between electrode end and furnace charge for smelting.

(2) For producing metallic silicon and yellow phosphorus in submerged arc furnace

Some carbon electrode with large size (eg.700mm-1400mm) is used for producing metallic silicon and yellow phosphorus in submerged arc furnace. The lower part of the carbon electrode is buried in the charge, forms an arc in the charge layer, the material will be smelted by the heat energy generated by the resistance of the charge. For example, about 100kg of graphite electrode is consumed for 1 ton of metallic silicon.

(3)For producing corundum in electric furnace

(4)Used for processing special-shaped graphite products

The blank of graphite electrode is also used to process various special-shaped graphite prod

The Production Processes of Graphite Electrode

The Chemical and Physical Indexes of HP Graphite Electrode

| Item | Unit | RP | |

| φ75-φ800mm | |||

| Resistivity | Electrode | μΩm | 7.0-10.0 |

| Nipple | 4.0-4.5 | ||

| Modulus of Rupture | Electrode | Mpa | 8.0-10.0 |

| Nipple | 19.0-22.0 | ||

| Young’s Modulus | Electrode | GPa | 7.0-9.3 |

| Nipple | 12.0-14.0 | ||

| Bulk Density | Electrode | g/cm3 | 1.53-1.56 |

| Nipple | 1.70-1.74 | ||

| CTE (100-600℃) | Electrode | 10-6/℃ | 2.2-2.6 |

| Nipple | 2.0-2.5 | ||

| Ash | % | 0.5 | |

The Current Carrying Capacity of Graphite Electrode

|

Item |

Nominal Diameter mm |

Current Carrying Capacity A |

Current Density A/cm2 |

|

RP Graphite Electrode |

200 |

5000-6900 |

15-21 |

|

250 |

7000-10000 |

14-20 |

|

|

300 |

10000-13000 |

14-18 |

|

|

350 |

13500-18000 |

14-18 |

|

|

400 |

18000-23500 |

14-18 |

|

|

450 |

22000-27000 |

13-17 |

|

|

500 |

25000-32000 |

13-16 |

|

|

550 |

30000-42000 |

13-16 |

|

|

600 |

40000-53000 |

13-16 |

Dimension of 4TPI Nipples and Socket

|

Nominal Diameter |

Nipple Type |

Sizes of Nipple (mm) |

Sizes of Socket |

Thread |

|||||

|

mm |

inch |

D |

L |

d2 |

l

|

d1 |

H |

mm |

|

|

Deviation (-0.5-0) |

Deviation (-1-0) |

Deviation (-5-0) |

Deviation (0-0.5) |

Deviation (0-7) |

|||||

|

200 |

8’’ |

122T4N |

122.24 |

177.80 |

80 |

<7 |

115.92 |

94.90 |

6.35 |

|

250 |

10’’ |

152T4N |

152.40 |

190.50 |

108.00 |

146.08 |

101.30 |

||

|

300 |

12’’ |

177T4N |

177.80 |

215.90 |

129.20 |

171.48 |

114.00 |

||

|

350 |

14’’ |

203T4N |

203.20 |

254.00 |

148.20 |

196.88 |

133.00 |

||

|

400 |

16’’ |

222T4N |

222.25 |

304.80 |

158.80 |

215.93 |

158.40 |

||

|

400 |

16’’ |

222T4L |

222.25 |

355.60 |

150.00 |

215.93 |

183.80 |

||

|

450 |

18’’ |

241T4N |

241.30 |

304.80 |

177.90 |

234.98 |

158.40 |

||

|

450 |

18’’ |

241T4L |

241.30 |

355.60 |

169.42 |

234.98 |

183.80 |

||

|

500 |

20’’ |

269T4N |

269.88 |

355.60 |

198.00 |

263.56 |

183.80 |

||

|

500 |

20’’ |

269T4L |

269.88 |

457.20 |

181.08 |

263.56 |

234.60 |

||

|

550 |

22’’ |

298T4N |

298.45 |

355.60 |

226.58 |

292.13 |

183.80 |

||

|

550 |

22’’ |

298T4L |

298.45 |

457.20 |

209.65 |

292.13 |

234.60 |

||

|

600 |

24’’ |

317T4N |

317.5 |

355.60 |

245.63 |

311.18 |

183.80 |

||

|

600 |

24’’ |

317T4L |

317.5 |

457.20 |

228.70 |

311.18 |

234.60 |

||

|

650 |

26’’ |

355T4N |

355.60 |

457.20 |

266.79 |

349.28 |

234.60 |

||

|

650 |

26’’ |

355T4L |

355.60 |

558.80 |

249.86 |

349.28 |

285.40 |

||

|

700 |

28’’ |

374T4N |

374.65 |

457.20 |

285.84 |

368.33 |

234.60 |

||

|

700 |

28’’ |

374T4L |

374.65 |

558.80 |

268.91 |

368.33 |

285.40 |

||

|

750 |

30’’ |

406T4N |

406.4 |

584.20 |

296.42 |

400.08 |

298.10 |

||

|

750 |

30’’ |

406T4L |

406.4 |

609.60 |

292.19 |

400.08 |

310.80 |

||

|

800 |

32’’ |

431T4N |

431.8 |

635.00 |

313.36 |

425.48 |

325.50 |

||

|

800 |

32’’ |

431T4L |

431.8 |

685.80 |

304.89 |

425.48 |

348.90 |

||

Dimension of 3TPI Nipples and Socket

|

Nominal Diameter |

Nipple Type |

Sizes of Nipple (mm) |

Sizes of Socket |

Thread |

|||||

|

mm |

inch |

D |

L |

d2 |

l

|

d1 |

H |

mm |

|

|

Deviation (-0.5-0) |

Deviation (-1-0) |

Deviation (-5-0) |

Deviation (0-0.5) |

Deviation (0-7) |

|||||

|

250 |

10’’ |

155T3N |

155.57 |

220.00 |

103.80 |

<7 |

147.14 |

116.00 |

6.35 |

|

300 |

12’’ |

177T3N |

177.16 |

270.90 |

116.90 |

168.73 |

141.50 |

||

|

350 |

14’’ |

215T3N |

215.90 |

304.80 |

150.00 |

207.47 |

158.40 |

||

|

400 |

16’’ |

215T3L |

215.90 |

304.80 |

150.00 |

207.47 |

158.40 |

||

|

400 |

16’’ |

241T3N |

241.30 |

338.70 |

169.80 |

232.87 |

175.30 |

||

|

450 |

18’’ |

241T3L |

241.30 |

338.70 |

169.80 |

232.87 |

175.30 |

||

|

450 |

18’’ |

273T3N |

273.05 |

355.60 |

198.70 |

264.62 |

183.80 |

||

|

500 |

20’’ |

273T3L |

273.05 |

355.60 |

198.70 |

264.62 |

183.80 |

||

|

500 |

20’’ |

298T3N |

298.45 |

372.60 |

221.30 |

290.02 |

192.20 |

||

|

550 |

22’’ |

298T3N |

298.45 |

372.60 |

221.30 |

290.02 |

192.20 |

||

3TPI Thread Detail

4TPI Thread Detail

Reference of Torque

|

Diameter |

mm |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

650 |

700 |

|

inch |

10’’ |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

Torque (N.m) |

400-450 |

500-650 |

700-950 |

850-1150 |

1050-1400 |

1300-1700 |

1850-2400 |

2300-3000 |

3900-4300 |

4400-5200 |

|

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Trending Products Graphite Electrode Arc Furnace - RP Graphite Electrode for Ladle Furnace – MORKIN , The product will supply to all over the world, such as: UK, Salt Lake City, Greenland, We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.