UHP Graphite Electrode for EAF/LF

Watch Us in Action!

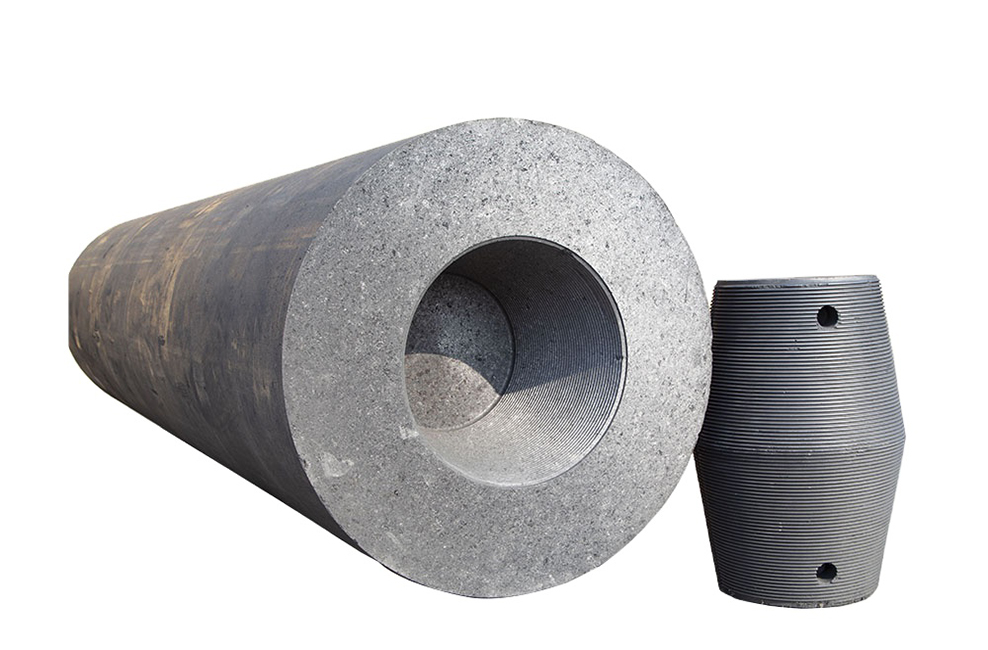

Ultra high power (UHP) graphite electrode is mainly made of high-grade needle coke as raw materials and coal asphalt as binder through calcination, batching, kneading, molding, baking, impregnation, graphitization and machining. Its graphitization heat treatment should be carried out in the Acheson graphitization furnace or Length-wise graphitization furnace. The graphitization temperature is up to 2800 ~ 3000 ℃, to make sure that the amorphous disordered carbon could be transformed into three-dimensional ordered graphite crystalline structure.

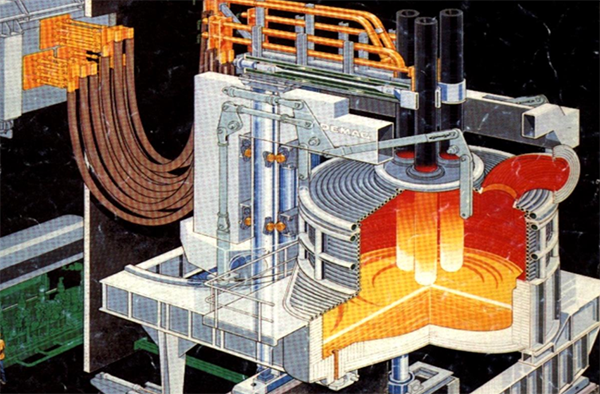

Ⅰ. For steel making in EAF/LF

Ⅱ. For producing metallic silicon and yellow phosphorus in submerged arc furnace

Ⅲ. For producing corundum in electric furnace

Ⅳ. Used for processing special-shaped graphite products

|

Item |

Unit |

UHP |

||

|

φ250-φ500mm |

φ550-φ700mm |

|||

|

Resistivity |

Electrode |

μΩm |

4.5-5.8 |

4.6-5.5 |

|

Nipple |

3.5-3.8 |

3.5-3.8 |

||

|

Modulus of Rupture |

Electrode |

Mpa |

10.0-14.0 |

10.0-14.0 |

|

Nipple |

20.0-24.0 |

22.0-26.0 |

||

|

Young's Modulus |

Electrode |

GPa |

9.0-13.0 |

10.0-14.0 |

|

Nipple |

15.0-18.0 |

16.0-19.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.70-1.74 |

1.72-1.74 |

|

Nipple |

1.78-1.82 |

1.80-1.84 |

||

|

CTE (100-600℃) |

Electrode |

10-6/℃ |

1.1-1.4 |

1.1-1.4 |

|

Nipple |

0.9-1.2 |

0.9-1.2 |

||

|

Ash |

% |

0.3 |

0.3 |

|

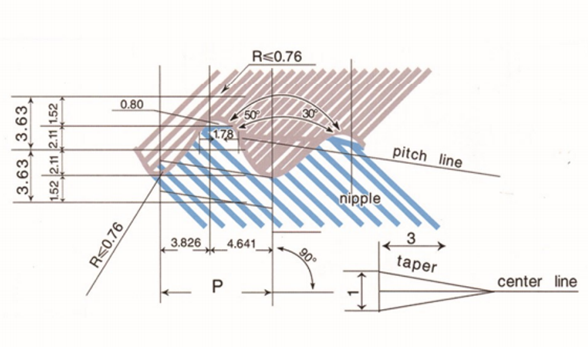

3TPI Thread Detail of Graphite Nipple

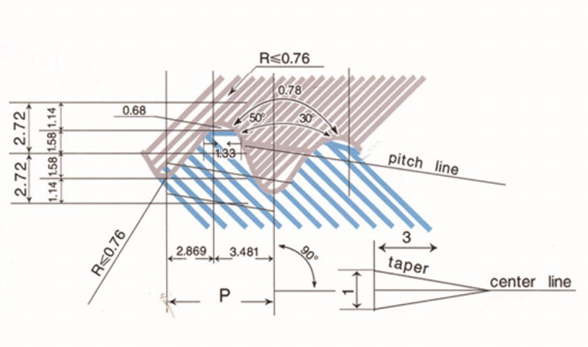

4TPI Thread Detail of Graphite Nipple