Short Lead Time for Graphite Electrode Rp 225mm T3n - HP Graphite Electrode for Steel Making – MORKIN

Short Lead Time for Graphite Electrode Rp 225mm T3n - HP Graphite Electrode for Steel Making – MORKIN Detail:

The Introduction of HP Graphite Electrode

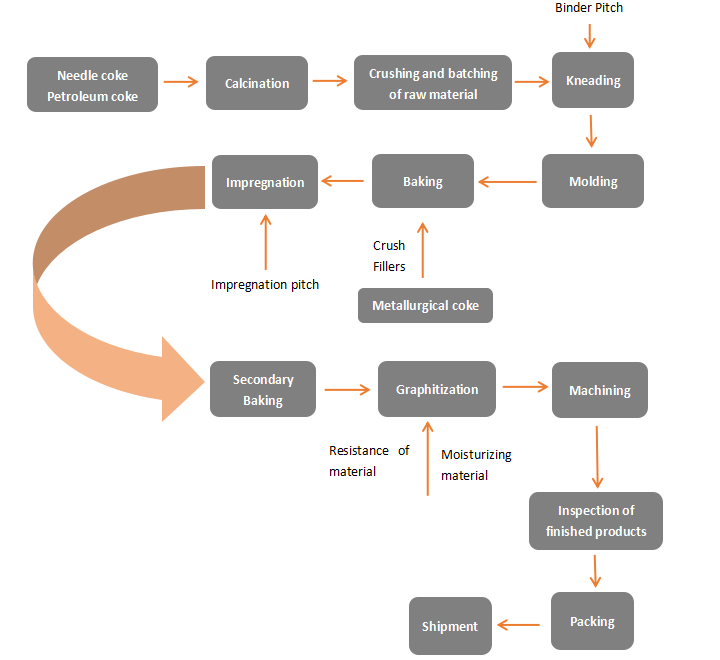

High power graphite electrode is produced by low-sulfur content petroleum coke (or needle coke) as raw materials and coal asphalt as binder through calcination, crushing, batching, kneading, molding, baking, impregnation, rebaking, graphitization and machining. Its physical and mechanical properties are higher than regular power graphite electrode, such as low resistivity and large current density.

The Application of HP Graphite Electrode

(1) For steel smelting in electric arc furnace/ladle furnace

(2) HP Graphite electrode is mainly used in Electric arc furnace for steel making. When graphite electrode is working in EAF, the current will be introduced by graphite electrode into the furnace, and there will be heat source which is generated by electric arc between electrode end and furnace charge for smelting.

(3)For corundum smelting in electric furnace

(4)Used for processing special-shaped graphite products

The blank of graphite electrode is also used to process various special-shaped graphite prod and graphite crucible,etc..

The Production Processes of Graphite Electrode

The Chemical and Physical Indexes of HP Graphite Electrode

| Item

|

Unit

|

HP | |

| φ200-φ700mm | |||

| Resistivity | Electrode | μΩm | 5.8-6.6 |

| Nipple | 3.5-4.0 | ||

| Modulus of Rupture | Electrode | Mpa | 10.0-13.0 |

| Nipple | 20.0-23.0 | ||

| Young’s Modulus | Electrode | GPa | 8.0-12.0 |

| Nipple | 14.0-16.0 | ||

| Bulk Density | Electrode | g/cm3 | 1.64-1.68 |

| Nipple | 1.75-1.80 | ||

| CTE (100-600℃) | Electrode | 10-6/℃ | 1.6-1.9 |

| Nipple | 1.1-1.4 | ||

| Ash | % | 0.3 | |

The Current Carrying Capacity of Graphite Electrode

|

Nominal Diameter |

RP |

HP |

UHP |

||||

|

Millimeter |

Inch |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

|

mm |

inch |

A |

A/cm2 |

A |

A/cm2 |

A |

A/cm2 |

|

75 |

3’’ |

1000-1400 |

22-31 |

||||

|

100 |

4’’ |

1500-2400 |

19-30 |

||||

|

130 |

5’’ |

2200-3400 |

17-26 |

||||

|

150 |

6’’ |

3000-4500 |

16-25 |

||||

|

200 |

8’’ |

5000-6900 |

15-21 |

5500-6900 |

18-25 |

||

|

250 |

10’’ |

7000-10000 |

14-20 |

6500-10000 |

18-25 |

8100-12200 |

20-30 |

|

300 |

12’’ |

10000-13000 |

14-18 |

13000-17400 |

17-24 |

15000-22000 |

20-30 |

|

350 |

14’’ |

13500-18000 |

14-18 |

17400-24000 |

17-24 |

20000-30000 |

20-30 |

|

400 |

16’’ |

18000-23500 |

14-18 |

21000-31000 |

16-24 |

25000-40000 |

19-30 |

|

450 |

18’’ |

22000-27000 |

13-17 |

25000-40000 |

15-24 |

32000-45000 |

19-27 |

|

500 |

20’’ |

25000-32000 |

13-16 |

30000-48000 |

15-24 |

38000-55000 |

18-27 |

|

550 |

22’’ |

28000-34000 |

12-14 |

34000-53000 |

14-22 |

45000-65000 |

18-27 |

|

600 |

24’’ |

30000-36000 |

11-13 |

38000-58000 |

13-21 |

50000-75000 |

18-26 |

|

650 |

26’’ |

32000-39000 |

10-12 |

41000-65000 |

12-20 |

60000-85000 |

18-25 |

|

700 |

28’’ |

34000-42000 |

9.0-11 |

45000-72000 |

12-19 |

70000-120000 |

18-30 |

Dimension of 4TPI Nipples and Socket

|

Nominal Diameter |

Nipple Type |

Sizes of Nipple (mm) |

Sizes of Socket |

Thread |

|||||

|

mm |

inch |

D |

L |

d2 |

l |

d1 |

H |

mm |

|

|

Deviation (-0.5-0) |

Deviation (-1-0) |

Deviation (-5-0) |

Deviation (0-0.5) |

Deviation (0-7) |

|||||

|

200 |

8’’ |

122T4N |

122.24 |

177.80 |

80 |

<7 |

115.92 |

94.90 |

6.35 |

|

250 |

10’’ |

152T4N |

152.40 |

190.50 |

108.00 |

146.08 |

101.30 |

||

|

300 |

12’’ |

177T4N |

177.80 |

215.90 |

129.20 |

171.48 |

114.00 |

||

|

350 |

14’’ |

203T4N |

203.20 |

254.00 |

148.20 |

196.88 |

133.00 |

||

|

400 |

16’’ |

222T4N |

222.25 |

304.80 |

158.80 |

215.93 |

158.40 |

||

|

400 |

16’’ |

222T4L |

222.25 |

355.60 |

150.00 |

215.93 |

183.80 |

||

|

450 |

18’’ |

241T4N |

241.30 |

304.80 |

177.90 |

234.98 |

158.40 |

||

|

450 |

18’’ |

241T4L |

241.30 |

355.60 |

169.42 |

234.98 |

183.80 |

||

|

500 |

20’’ |

269T4N |

269.88 |

355.60 |

198.00 |

263.56 |

183.80 |

||

|

500 |

20’’ |

269T4L |

269.88 |

457.20 |

181.08 |

263.56 |

234.60 |

||

|

550 |

22’’ |

298T4N |

298.45 |

355.60 |

226.58 |

292.13 |

183.80 |

||

|

550 |

22’’ |

298T4L |

298.45 |

457.20 |

209.65 |

292.13 |

234.60 |

||

|

600 |

24’’ |

317T4N |

317.5 |

355.60 |

245.63 |

311.18 |

183.80 |

||

|

600 |

24’’ |

317T4L |

317.5 |

457.20 |

228.70 |

311.18 |

234.60 |

||

|

650 |

26’’ |

355T4N |

355.60 |

457.20 |

266.79 |

349.28 |

234.60 |

||

|

650 |

26’’ |

355T4L |

355.60 |

558.80 |

249.86 |

349.28 |

285.40 |

||

|

700 |

28’’ |

374T4N |

374.65 |

457.20 |

285.84 |

368.33 |

234.60 |

||

|

700 |

28’’ |

374T4L |

374.65 |

558.80 |

268.91 |

368.33 |

285.40 |

||

|

750 |

30’’ |

406T4N |

406.4 |

584.20 |

296.42 |

400.08 |

298.10 |

||

|

750 |

30’’ |

406T4L |

406.4 |

609.60 |

292.19 |

400.08 |

310.80 |

||

|

800 |

32’’ |

431T4N |

431.8 |

635.00 |

313.36 |

425.48 |

325.50 |

||

|

800 |

32’’ |

431T4L |

431.8 |

685.80 |

304.89 |

425.48 |

348.90 |

||

Dimension of 3TPI Nipples and Socket

|

Nominal Diameter |

Nipple Type |

Sizes of Nipple (mm) |

Sizes of Socket |

Thread |

|||||

|

mm |

inch |

D |

L |

d2 |

l

|

d1 |

H |

mm |

|

|

Deviation (-0.5-0) |

Deviation (-1-0) |

Deviation (-5-0) |

Deviation (0-0.5) |

Deviation (0-7) |

|||||

|

250 |

10’’ |

155T3N |

155.57 |

220.00 |

103.80 |

<7 |

147.14 |

116.00 |

6.35 |

|

300 |

12’’ |

177T3N |

177.16 |

270.90 |

116.90 |

168.73 |

141.50 |

||

|

350 |

14’’ |

215T3N |

215.90 |

304.80 |

150.00 |

207.47 |

158.40 |

||

|

400 |

16’’ |

215T3L |

215.90 |

304.80 |

150.00 |

207.47 |

158.40 |

||

|

400 |

16’’ |

241T3N |

241.30 |

338.70 |

169.80 |

232.87 |

175.30 |

||

|

450 |

18’’ |

241T3L |

241.30 |

338.70 |

169.80 |

232.87 |

175.30 |

||

|

450 |

18’’ |

273T3N |

273.05 |

355.60 |

198.70 |

264.62 |

183.80 |

||

|

500 |

20’’ |

273T3L |

273.05 |

355.60 |

198.70 |

264.62 |

183.80 |

||

|

500 |

20’’ |

298T3N |

298.45 |

372.60 |

221.30 |

290.02 |

192.20 |

||

|

550 |

22’’ |

298T3N |

298.45 |

372.60 |

221.30 |

290.02 |

192.20 |

||

3TPI Thread Detail

4TPI Thread Detail

Reference of Torque

|

Diameter |

mm |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

650 |

700 |

|

inch |

10’’ |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

Torque (N.m) |

400-450 |

500-650 |

700-950 |

850-1150 |

1050-1400 |

1300-1700 |

1850-2400 |

2300-3000 |

3900-4300 |

4400-5200 |

|

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for Short Lead Time for Graphite Electrode Rp 225mm T3n - HP Graphite Electrode for Steel Making – MORKIN , The product will supply to all over the world, such as: Puerto Rico, Bangladesh, Czech, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and solutions and good service for domestic and international customers.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.