Low price for Graphite Carbon Electrodes For Steel Industries – Carbon Electrode for Silicon Smelting – MORKIN

Low price for Graphite Carbon Electrodes For Steel Industries – Carbon Electrode for Silicon Smelting – MORKIN Detail:

Main description

At present, graphite electrodes with higher price have been replaced in industrial silicon and yellow phosphorus smelting furnace. In the same capacity of submerged arc furnace, compared with graphite electrode, the diameter of carbon electrode can be made larger (now the domestic production can be φ650-φ1200mm carbon electrode, graphite electrode can only be φ 700mm), so that the arc belt in the furnace is wider, arc stability, ensure the hot melt efficiency, increase product output, reduce product power consumption. Ton ferrosilicon smelting cost reduced by 300-400 yuan, ton calcium carbide smelting cost reduced by more than 100 yuan.

Carbon electrode is energy saving, environmental protection products, the use of calcium carbide, ferroalloy ore furnace can greatly reduce smelting power consumption, reduce pollution. It is the replacement product of electrode paste. In the same capacity of submerged arc furnace, compared with the electrode paste self-baking electrode, it has the following characteristics: increase the smelting furnace output, reduce power consumption 15-20%; Reduce labor intensity (smelting 1 ton of ferroalloy electrode paste about 60kg, consumption of carbon electrode only about 12kg, reduce the number of electrode operation), simplify the production process; Avoid or reduce the “soft break” and “hard break” accidents that often occur in self-baking electrode, improve the working environment and save operating costs.

Specs

|

Item |

Length (mm) |

Bulk Density(g/cm3) |

Resistivity(μΩm) |

Modulus of Rupture(MPa) |

Young’s Modulus(GPa) |

Ash(%) |

CTE(10-6/℃) |

|

1020mm Carbon Electrode |

2450+/- 100 |

≧1.62 |

≦32 |

≧7 |

≦10 |

≦2 |

≦4.3*10-6 |

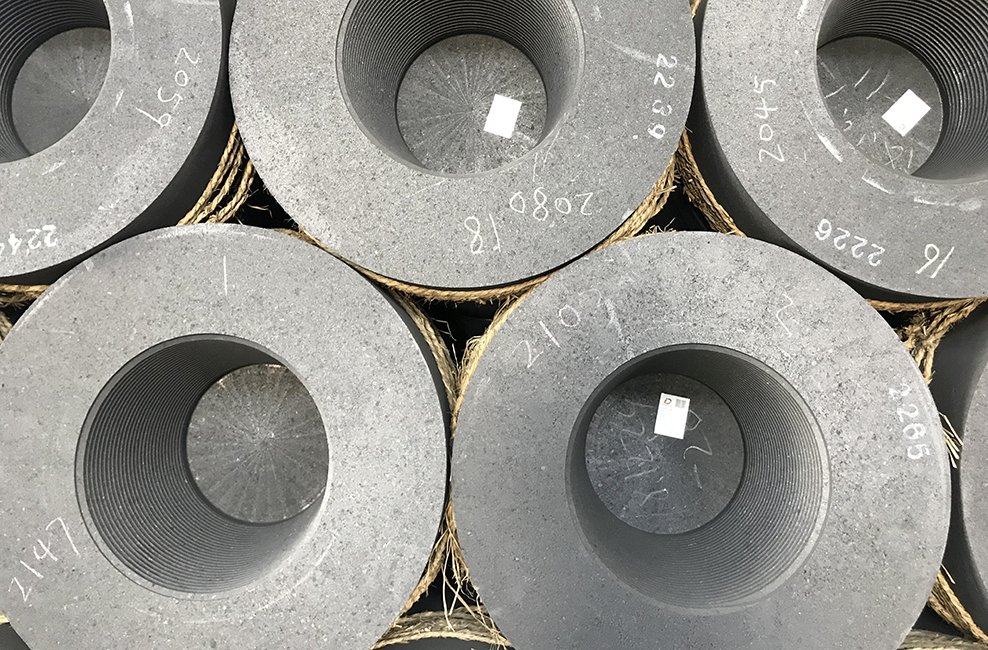

Product detail pictures:

Related Product Guide:

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we've been far more expert and more hard-working and do it in cost-effective way for Low price for Graphite Carbon Electrodes For Steel Industries – Carbon Electrode for Silicon Smelting – MORKIN , The product will supply to all over the world, such as: Philippines, Ireland, Denver, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!