Low MOQ for Graphite Electrode For Ladle Furnace - HP Graphite Electrode for Steel Making – MORKIN

Low MOQ for Graphite Electrode For Ladle Furnace - HP Graphite Electrode for Steel Making – MORKIN Detail:

High power graphite electrode is produced by low-sulfur content petroleum coke (or needle coke) as raw materials and coal asphalt as binder through calcination, crushing, batching, kneading, molding, baking, impregnation, rebaking, graphitization and machining. Its physical and mechanical properties are higher than regular power graphite electrode, such as low resistivity and large current density.

Ⅰ. For steel making in EAF/LF

Ⅱ. For precious metal smelting in arc furnace

Ⅲ. For producing corundum in electric furnace

Ⅳ. Used for processing special-shaped graphite products

|

Item |

Unit |

HP |

|

|

φ200-φ700mm |

|||

|

Resistivity |

Electrode |

μΩm |

5.8-6.6 |

|

Nipple |

3.5-4.0 |

||

|

Modulus of Rupture |

Electrode |

Mpa |

10.0-13.0 |

|

Nipple |

20.0-23.0 |

||

|

Young’s Modulus |

Electrode |

GPa |

8.0-12.0 |

|

Nipple |

14.0-16.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.64-1.68 |

|

Nipple |

1.75-1.80 |

||

|

CTE (100-600℃) |

Electrode |

10-6/℃ |

1.6-1.9 |

|

Nipple |

1.1-1.4 |

||

|

Ash |

% |

0.3 |

|

|

Nominal Diameter |

RP |

HP |

UHP |

||||

|

Millimeter |

Inch |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

|

mm |

Inch |

A |

A/cm2 |

A |

A/cm2 |

A |

A/cm2 |

|

75 |

3’’ |

1000-1400 |

22-31 |

||||

|

100 |

4’’ |

1500-2400 |

19-30 |

||||

|

130 |

5’’ |

2200-3400 |

17-26 |

||||

|

150 |

6’’ |

3000-4500 |

16-25 |

||||

|

200 |

8’’ |

5000-6900 |

15-21 |

5500-6900 |

18-25 |

||

|

250 |

10’’ |

7000-10000 |

14-20 |

6500-10000 |

18-25 |

8100-12200 |

20-30 |

|

300 |

12’’ |

10000-13000 |

14-18 |

13000-17400 |

17-24 |

15000-22000 |

20-30 |

|

350 |

14’’ |

13500-18000 |

14-18 |

17400-24000 |

17-24 |

20000-30000 |

20-30 |

|

400 |

16’’ |

18000-23500 |

14-18 |

21000-31000 |

16-24 |

25000-40000 |

19-30 |

|

450 |

18’’ |

22000-27000 |

13-17 |

25000-40000 |

15-24 |

32000-45000 |

19-27 |

|

500 |

20’’ |

25000-32000 |

13-16 |

30000-48000 |

15-24 |

38000-55000 |

18-27 |

|

550 |

22’’ |

28000-34000 |

12-14 |

34000-53000 |

14-22 |

45000-65000 |

18-27 |

|

600 |

24’’ |

30000-36000 |

11-13 |

38000-58000 |

13-21 |

50000-75000 |

18-26 |

|

650 |

26’’ |

32000-39000 |

10-12 |

41000-65000 |

12-20 |

60000-85000 |

18-25 |

|

700 |

28’’ |

34000-42000 |

9.0-11 |

45000-72000 |

12-19 |

70000-120000 |

18-30 |

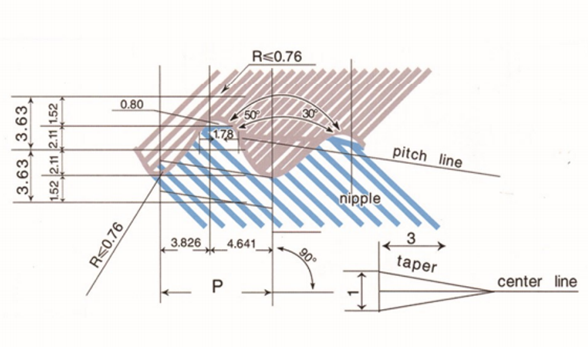

3TPI Thread Detail of Graphite Nipple

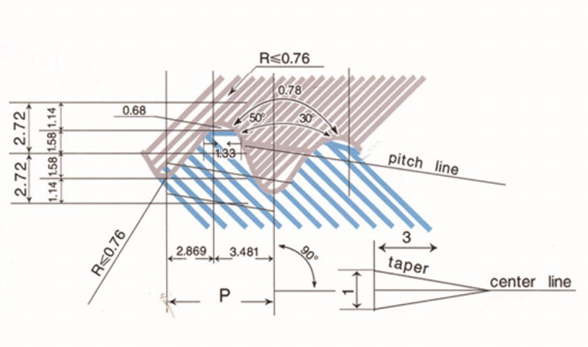

4TPI Thread Detail of Graphite Nipple

Pre-Sale Service

Experienced technical and sales personnel form a professional team to provide product consultation and the most competitive price support in the market.

In-sale Service

Support third-party inspection, provide documents, and cooperate with customers’ shipping requirements.

After-sale Service

Dispatch technical team do the on-spot visit and communication with customer before and after sales. Track and guide the use of graphite electrodes in the whole process, wait for customer’s feedback. Any adverse reactions caused by product quality, the new batch of products will be replaced for end user.

Watch Us in Action!

Large Stock

There is large stock of RP/HP/UHP graphite electrodes from 100-700mm in diameter, which can be shipped to any port in China within 7 days.

Inspection

Professional inspection team for shipment and support third-party inspection (SGS).

24 Hours

Professional technician and sales team track the use of customers, and respond to any problems within 24 hours.

Solution

Supply technical support and solutions for every customer for any issues when producing in furnace

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Low MOQ for Graphite Electrode For Ladle Furnace - HP Graphite Electrode for Steel Making – MORKIN , The product will supply to all over the world, such as: Venezuela, Angola, Thailand, To get more information about us as well as see all our products, please visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.