Good quality China Manufacturer Graphite Electrodes - UHP Graphite Electrode for EAF/LF – MORKIN

Good quality China Manufacturer Graphite Electrodes - UHP Graphite Electrode for EAF/LF – MORKIN Detail:

Feature

1.Resistivity is lower, allowing larger current density

2.Smaller linear expansion coefficient

3.Excellent thermal shock resistance.

4.Good electric conduction

5.High temperature resistance and good stability

6.Good chemical stability

application

(1) For steel making in EAF/LF

Graphite electrode is mainly used in Electric arc furnace for steel smelting. When graphite electrode is working in EAF, the current will be introduced by graphite electrode into the furnace, and there will be heat source which is generated by electric arc between electrode end and furnace charge for smelting.

(2) For producing metallic silicon and yellow phosphorus in submerged arc furnace

Some carbon electrode with large size (eg.700mm-1400mm) is used for producing metallic silicon and yellow phosphorus in submerged arc furnace. The lower part of the carbon electrode is buried in the charge, forms an arc in the charge layer, the material will be smelted by the heat energy generated by the resistance of the charge. For example, about 100kg of graphite electrode is consumed for 1 ton of metallic silicon.

(3)For producing corundum in electric furnace

(4)Used for processing special-shaped graphite products

The blank of graphite electrode is also used to process various special-shaped graphite prod

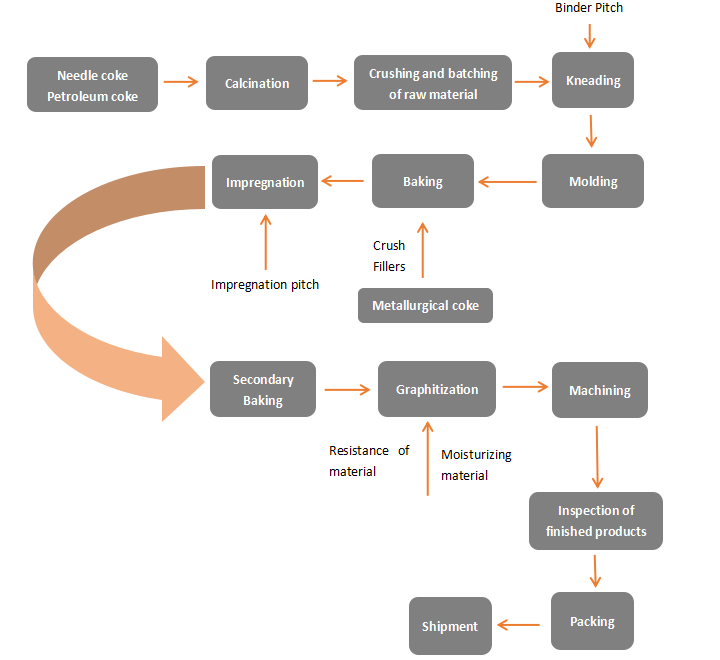

The Production Processes of Graphite Electrode

The Chemical and Physical Indexes of UHP Graphite Electrode

| Item | Unit | HP | |

| φ200-φ700mm | |||

| Resistivity | Electrode | μΩm | 5.8-6.6 |

| Nipple | 3.5-4.0 | ||

| Modulus of Rupture | Electrode | Mpa | 10.0-13.0 |

| Nipple | 20.0-23.0 | ||

| Young’s Modulus | Electrode | GPa | 8.0-12.0 |

| Nipple | 14.0-16.0 | ||

| Bulk Density | Electrode | g/cm3 | 1.64-1.68 |

| Nipple | 1.75-1.80 | ||

| CTE (100-600℃) | Electrode | 10-6/℃ | 1.6-1.9 |

| Nipple | 1.1-1.4 | ||

| Ash | % | 0.3 | |

The Current Carrying Capacity of Graphite Electrode

|

Nominal Diameter |

RP |

HP |

UHP |

||||

|

Millimeter |

Inch |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

Current Carrying Capacity |

Current Density |

|

mm |

inch |

A |

A/cm2 |

A |

A/cm2 |

A |

A/cm2 |

|

75 |

3’’ |

1000-1400 |

22-31 |

|

|

||

|

100 |

4’’ |

1500-2400 |

19-30 |

||||

|

130 |

5’’ |

2200-3400 |

17-26 |

||||

|

150 |

6’’ |

3000-4500 |

16-25 |

||||

|

200 |

8’’ |

5000-6900 |

15-21 |

5500-6900 |

18-25 |

||

|

250 |

10’’ |

7000-10000 |

14-20 |

6500-10000 |

18-25 |

8100-12200 |

20-30 |

|

300 |

12’’ |

10000-13000 |

14-18 |

13000-17400 |

17-24 |

15000-22000 |

20-30 |

|

350 |

14’’ |

13500-18000 |

14-18 |

17400-24000 |

17-24 |

20000-30000 |

20-30 |

|

400 |

16’’ |

18000-23500 |

14-18 |

21000-31000 |

16-24 |

25000-40000 |

19-30 |

|

450 |

18’’ |

22000-27000 |

13-17 |

25000-40000 |

15-24 |

32000-45000 |

19-27 |

|

500 |

20’’ |

25000-32000 |

13-16 |

30000-48000 |

15-24 |

38000-55000 |

18-27 |

|

550 |

22’’ |

28000-34000 |

12-14 |

34000-53000 |

14-22 |

45000-65000 |

18-27 |

|

600 |

24’’ |

30000-36000 |

11-13 |

38000-58000 |

13-21 |

50000-75000 |

18-26 |

|

650 |

26’’ |

32000-39000 |

10-12 |

41000-65000 |

12-20 |

60000-85000 |

18-25 |

|

700 |

28’’ |

34000-42000 |

9.0-11 |

45000-72000 |

12-19 |

70000-120000 |

18-30 |

Dimension of 4TPI Nipples and Socket

|

Nominal Diameter |

Nipple Type |

Sizes of Nipple (mm) |

Sizes of Socket |

Thread |

|||||

|

mm |

inch |

D |

L |

d2 |

l

|

d1 |

H |

mm |

|

|

Deviation (-0.5-0) |

Deviation (-1-0) |

Deviation (-5-0) |

Deviation (0-0.5) |

Deviation (0-7) |

|||||

|

200 |

8’’ |

122T4N |

122.24 |

177.80 |

80 |

<7 |

115.92 |

94.90 |

6.35 |

|

250 |

10’’ |

152T4N |

152.40 |

190.50 |

108.00 |

146.08 |

101.30 |

||

|

300 |

12’’ |

177T4N |

177.80 |

215.90 |

129.20 |

171.48 |

114.00 |

||

|

350 |

14’’ |

203T4N |

203.20 |

254.00 |

148.20 |

196.88 |

133.00 |

||

|

400 |

16’’ |

222T4N |

222.25 |

304.80 |

158.80 |

215.93 |

158.40 |

||

|

400 |

16’’ |

222T4L |

222.25 |

355.60 |

150.00 |

215.93 |

183.80 |

||

|

450 |

18’’ |

241T4N |

241.30 |

304.80 |

177.90 |

234.98 |

158.40 |

||

|

450 |

18’’ |

241T4L |

241.30 |

355.60 |

169.42 |

234.98 |

183.80 |

||

|

500 |

20’’ |

269T4N |

269.88 |

355.60 |

198.00 |

263.56 |

183.80 |

||

|

500 |

20’’ |

269T4L |

269.88 |

457.20 |

181.08 |

263.56 |

234.60 |

||

|

550 |

22’’ |

298T4N |

298.45 |

355.60 |

226.58 |

292.13 |

183.80 |

||

|

550 |

22’’ |

298T4L |

298.45 |

457.20 |

209.65 |

292.13 |

234.60 |

||

|

600 |

24’’ |

317T4N |

317.5 |

355.60 |

245.63 |

311.18 |

183.80 |

||

|

600 |

24’’ |

317T4L |

317.5 |

457.20 |

228.70 |

311.18 |

234.60 |

||

|

650 |

26’’ |

355T4N |

355.60 |

457.20 |

266.79 |

349.28 |

234.60 |

||

|

650 |

26’’ |

355T4L |

355.60 |

558.80 |

249.86 |

349.28 |

285.40 |

||

|

700 |

28’’ |

374T4N |

374.65 |

457.20 |

285.84 |

368.33 |

234.60 |

||

|

700 |

28’’ |

374T4L |

374.65 |

558.80 |

268.91 |

368.33 |

285.40 |

||

|

750 |

30’’ |

406T4N |

406.4 |

584.20 |

296.42 |

400.08 |

298.10 |

||

|

750 |

30’’ |

406T4L |

406.4 |

609.60 |

292.19 |

400.08 |

310.80 |

||

|

800 |

32’’ |

431T4N |

431.8 |

635.00 |

313.36 |

425.48 |

325.50 |

||

|

800 |

32’’ |

431T4L |

431.8 |

685.80 |

304.89 |

425.48 |

348.90 |

||

Dimension of 3TPI Nipples and Socket

|

Nominal Diameter |

Nipple Type |

Sizes of Nipple (mm) |

Sizes of Socket |

Thread |

|||||

|

mm |

inch |

D |

L |

d2 |

l

|

d1 |

H |

mm |

|

|

Deviation (-0.5-0) |

Deviation (-1-0) |

Deviation (-5-0) |

Deviation (0-0.5) |

Deviation (0-7) |

|||||

|

250 |

10’’ |

155T3N |

155.57 |

220.00 |

103.80 |

<7 |

147.14 |

116.00 |

6.35 |

|

300 |

12’’ |

177T3N |

177.16 |

270.90 |

116.90 |

168.73 |

141.50 |

||

|

350 |

14’’ |

215T3N |

215.90 |

304.80 |

150.00 |

207.47 |

158.40 |

||

|

400 |

16’’ |

215T3L |

215.90 |

304.80 |

150.00 |

207.47 |

158.40 |

||

|

400 |

16’’ |

241T3N |

241.30 |

338.70 |

169.80 |

232.87 |

175.30 |

||

|

450 |

18’’ |

241T3L |

241.30 |

338.70 |

169.80 |

232.87 |

175.30 |

||

|

450 |

18’’ |

273T3N |

273.05 |

355.60 |

198.70 |

264.62 |

183.80 |

||

|

500 |

20’’ |

273T3L |

273.05 |

355.60 |

198.70 |

264.62 |

183.80 |

||

|

500 |

20’’ |

298T3N |

298.45 |

372.60 |

221.30 |

290.02 |

192.20 |

||

|

550 |

22’’ |

298T3N |

298.45 |

372.60 |

221.30 |

290.02 |

192.20 |

||

3TPI Thread Detail

4TPI Thread Detail

Reference of Torque

|

Diameter |

mm |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

650 |

700 |

|

inch |

10’’ |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

Torque (N.m) |

400-450 |

500-650 |

700-950 |

850-1150 |

1050-1400 |

1300-1700 |

1850-2400 |

2300-3000 |

3900-4300 |

4400-5200 |

|

Product detail pictures:

Related Product Guide:

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for Good quality China Manufacturer Graphite Electrodes - UHP Graphite Electrode for EAF/LF – MORKIN , The product will supply to all over the world, such as: Indonesia, Riyadh, Sao Paulo, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.